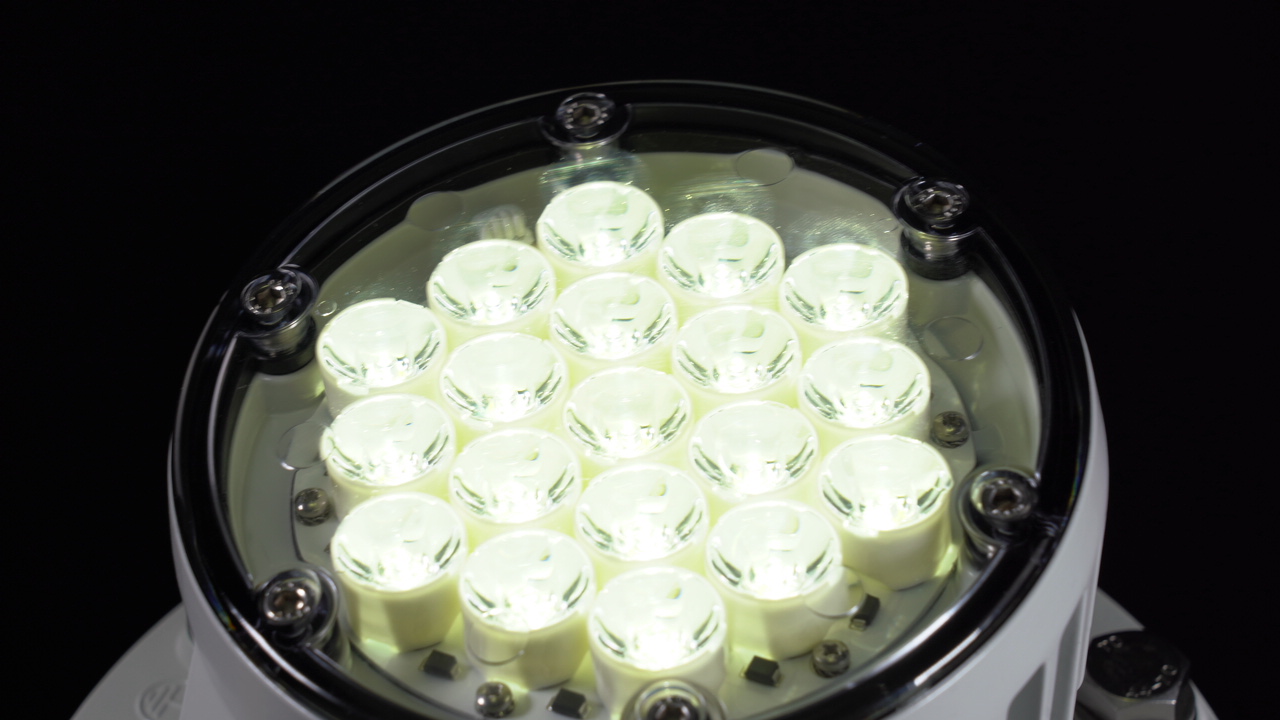

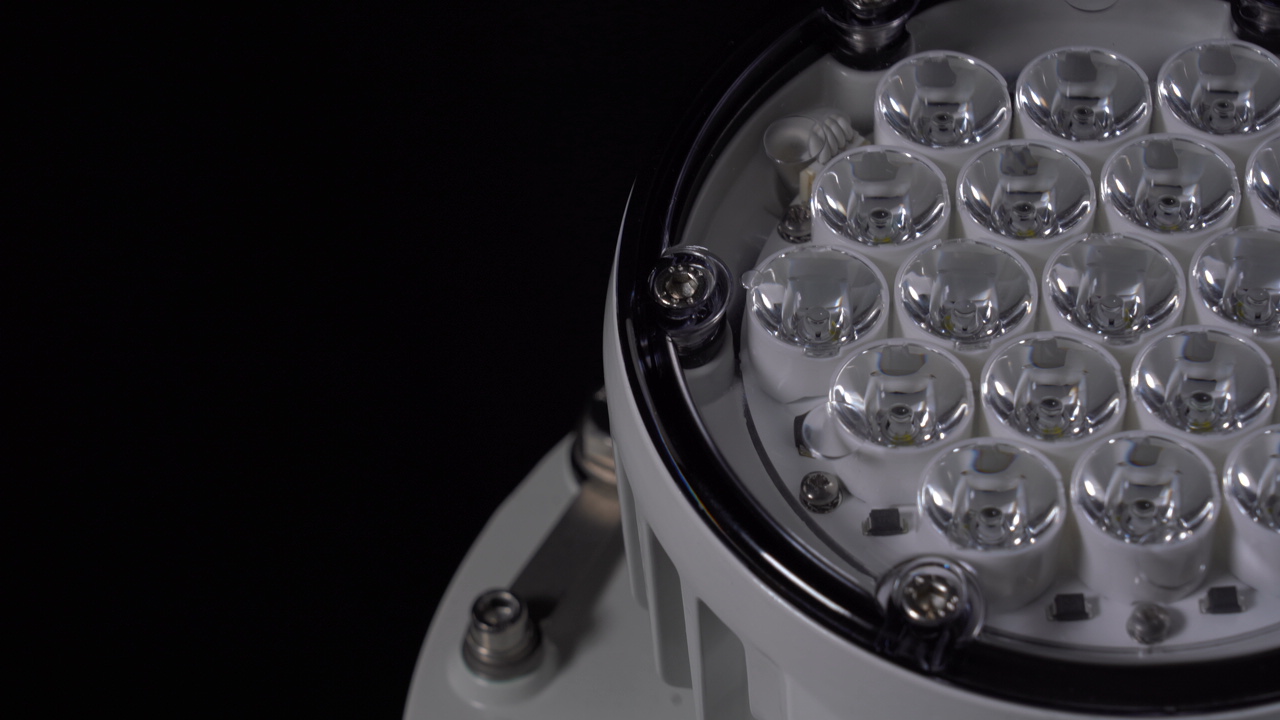

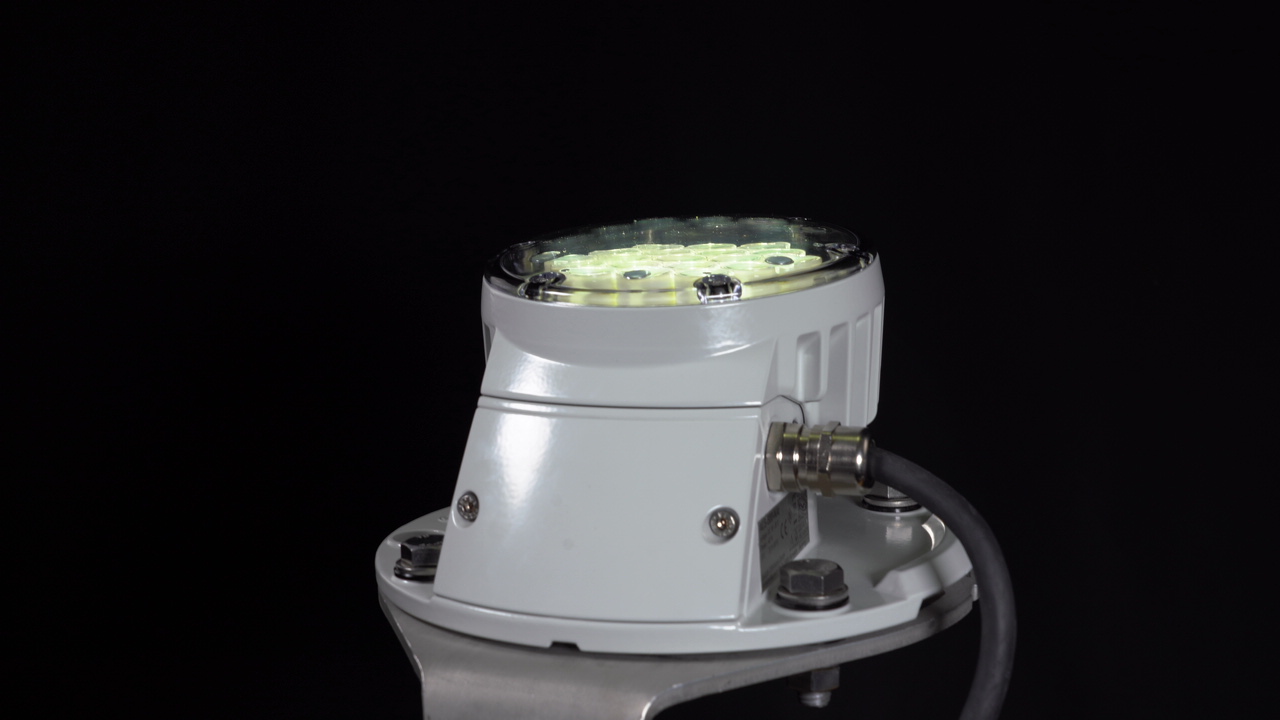

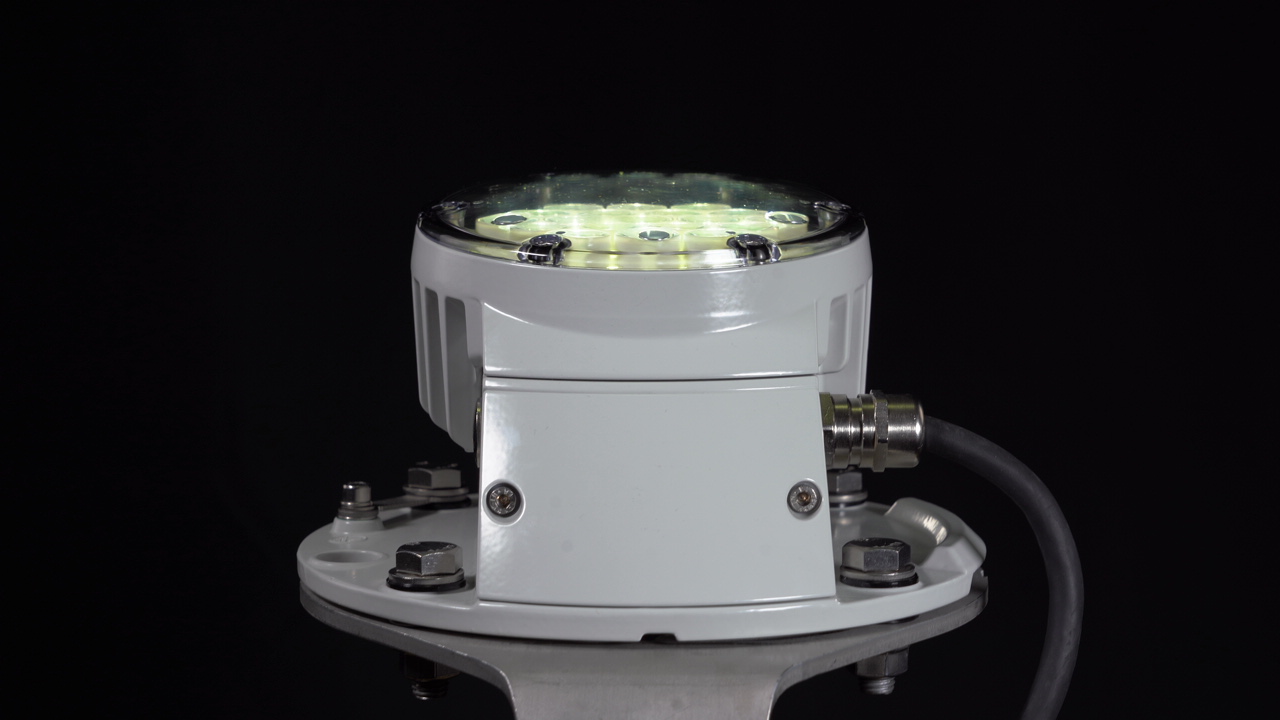

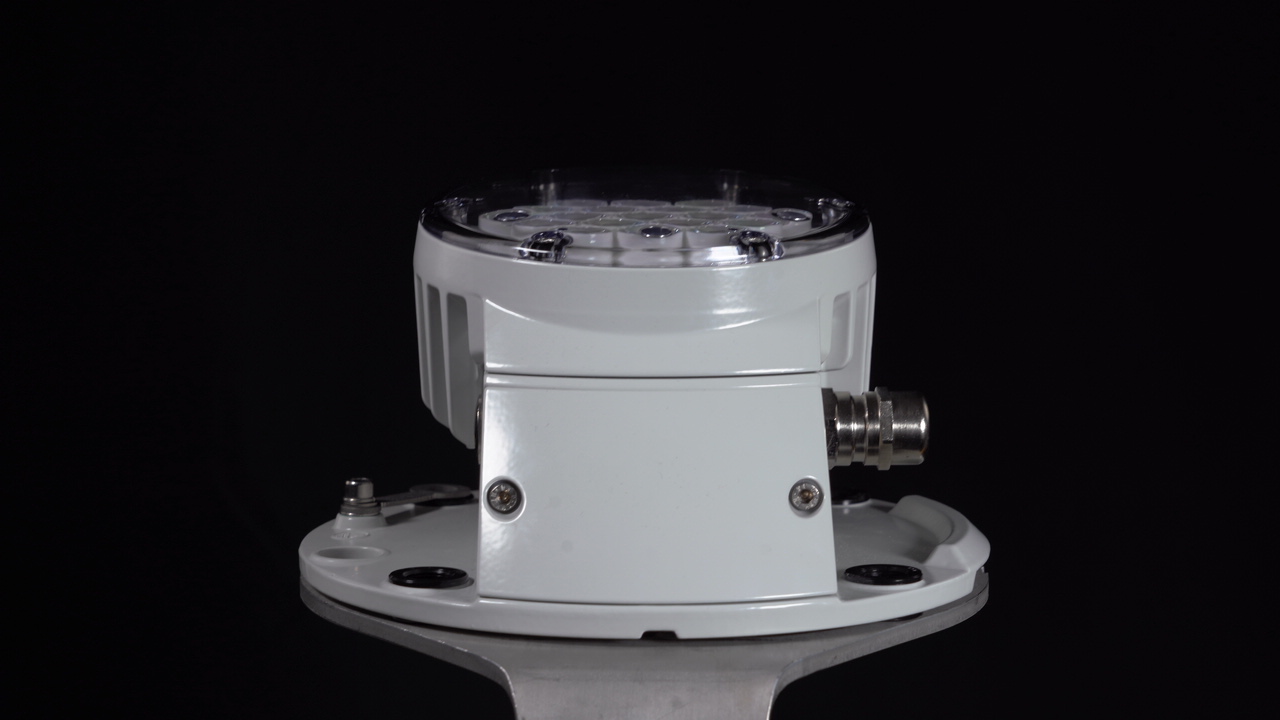

ALS-500-NAi

Helicopter Corridor Floodlight

- Maintenance-free LED technology

- Anodised, powder-coated aluminium housing

- Standard NAi bus interface for power supply and communication

- Adjustable intensity

- Power consumption 40 W at maximum operating luminous intensity (70 000 cd)

- Beam angle 8° (FWHM)

The ALS 500 NAi satisfies the WSV’s2 requirements of the technical standard “Tower lighting at wind turbines for additional marking of the arrival and departure corridors for helicopters in offshore wind farms”. So that the lateral limiting of the corridor to the helicopter landing platform is easily recognisable during approach and take- off, the neighbouring wind turbines are illuminated for a limited period on the side facing the corridor.The floodlight’s integrated NAi bus interface is used to supply power, to control the intensity and switching status, and to transmit status and error messages to the central NAi Controller, so that they are available to the central SCADA system.The integrated operational monitoring detects LED failures, errors in the control electronics as well as supply voltage problems, excess temperature and interruptions in communication.

| DIMENSIONS, WEIGHT | |

| Diameter optics | 155 mm |

| Diameter mounting foot | 230 mm |

| Height | 130 mm |

| Weight | 2.72 kg |

| ELECTRICAL CONNECTION | |

| Electrical connection | Spring terminal block, max. 2.5 mm2 |

| Operating voltage VIN | 19 to 36 V DC |

| Power consumption (VIN=24 V DC - max. intensity) | 40 W |

| OPTICAL SYSTEM | |

| Light colour | 4750 K |

| Maximum luminous intensity (along the optical axis) | 70 000 cd |

| Beam angle | 8° FWHM |

| RELIABILITY | |

| MTBF Electronics | 2 130 000 h |

| Minimum LED Lifetime | 60 000 h |

| ENVIRONMENTAL CONDITIONS | |

| Regulations | IEC 60945, device type ‘exposed’ |

| Ambient temperature (operation) | -40℃ to 55 °C |

| Ambient temperature (storage / transport) | -40℃ to 70 °C |

| Power consumption | see table |

| Humidity (operation / storage / transport) | max. 95 % acc. to IEC 60945 |

| Atmospheric pressure (operation / storage / transport) | 80 kPa to 108 kPa |

| Degree of protection (acc. to IEC 60529) | IP67 |

| Protection class | Class III |

| MECHANICAL REQUIREMENTS | |

| Vibration testing sinusoidal vibrations | acc. to IEC 60945 |

| MATERIAL | |

| Housing (Device foot, head, cover for socket) | Anodised, powder-coated aluminium (AlSi12) |

| Lens | PMMA |

| Cover LED insert | MAKROLON® (PC) |

| Cable gland | Nickel-plated brass |

| Earthing connection | Nickel-plated brass |

| Cover indicator LED | PMMA |

| Insulation sleeve | PA |

| Seals | TPE, injection-molded |

| Pressure compensation valve for socket and housing | PTFE membrane |